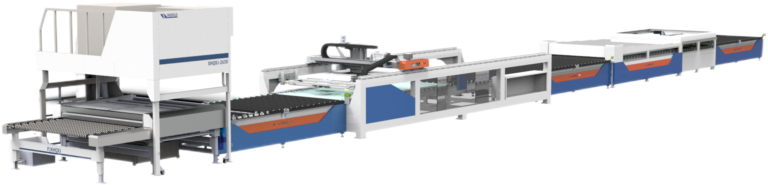

The demand for energy-efficient buildings has driven the need for high-quality insulating glass (IG). As a result, the glass industry continuously seeks to improve the production process. Advanced insulating glass production lines (IG lines) play a critical role in enhancing the overall quality of IG units.

How IG Lines Improve Quality

**1. Precision in Assembly:**

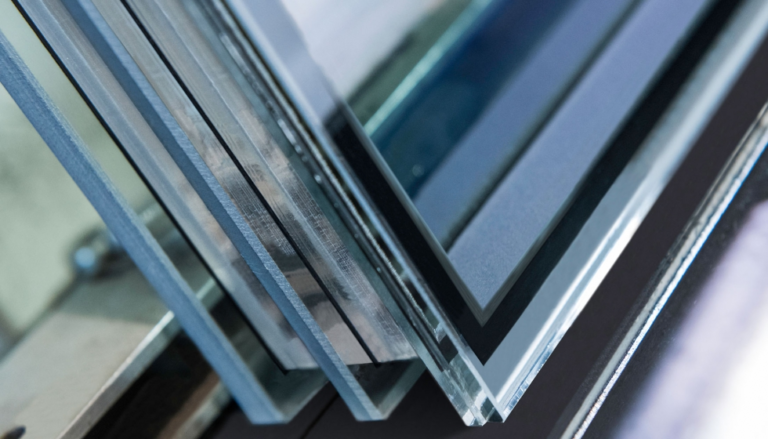

Modern IG lines are equipped with advanced technology that ensures precise alignment and assembly of glass panes. Automated systems reduce human error, leading to consistent production of high-quality IGUs. Precise assembly minimizes the risk of thermal bridging and improves the overall insulation performance.

**2. Consistent Application of Sealants:**

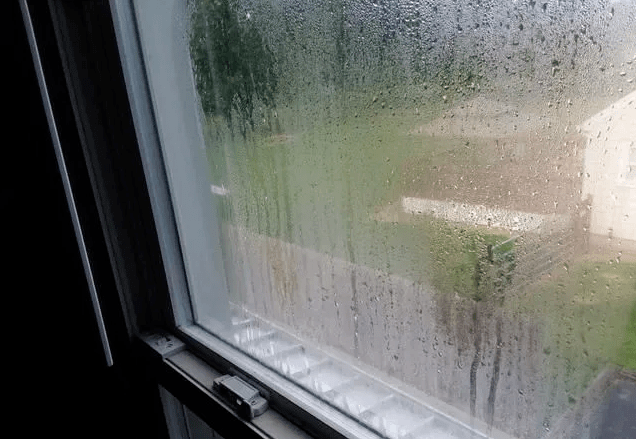

Sealant application is a critical step in the production of IGUs. IG lines ensure the consistent and accurate application of sealants, which is essential for preventing moisture ingress and maintaining the integrity of the unit over time. Properly sealed IGUs have a longer lifespan and offer better thermal insulation.

**3. Integration with flexible Warm Edge Spacers: **

The integration of flexible warm edge spacers in IGU production significantly enhances the thermal performance of IGUs. Warm edge spacers reduce heat transfer at the edges of the glass, leading to lower U-values and improved energy efficiency. Advanced IG lines allow for seamless incorporation of these spacers, ensuring that every unit meets the highest standards of thermal insulation.

For manufacturers, investing in advanced IG lines is not just about improving quality; it’s about staying competitive in an evolving market. The ability to produce high-quality IGUs with superior thermal performance, durability, and longevity gives manufacturers a significant edge. Additionally, the integration of warm edge spacers in the production process meets the growing demand for energy-efficient solutions, making IGUs more appealing to Eco-conscious consumers.