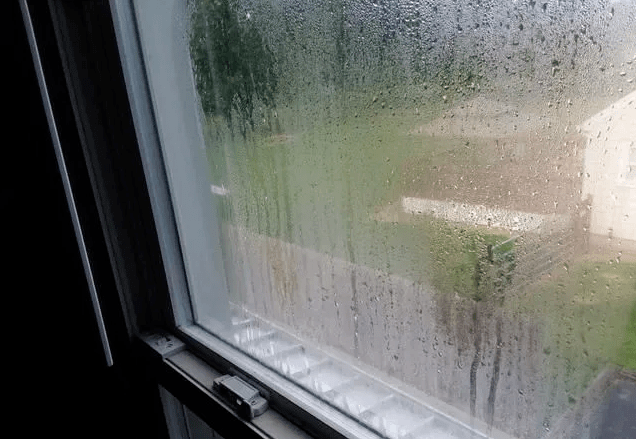

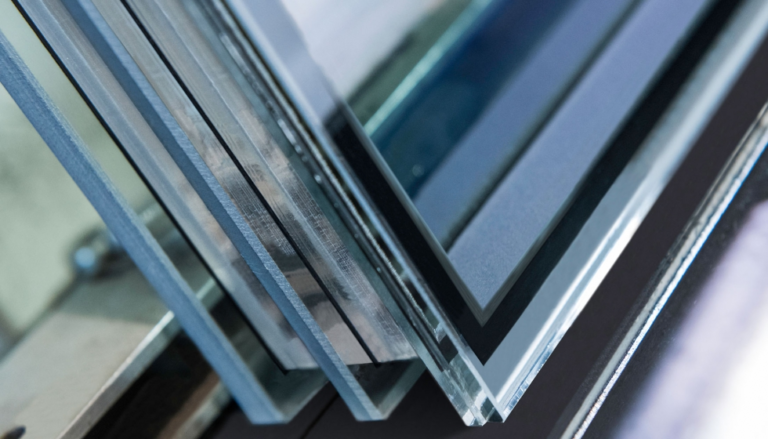

In today’s construction industry, energy efficiency is paramount, and insulating glass (IG) units are at the forefront of this movement. As demand for IG units rises, so does the need for efficient, high-quality production equipment. This comprehensive buying guide will help you to purchasing the MBS IG production line.

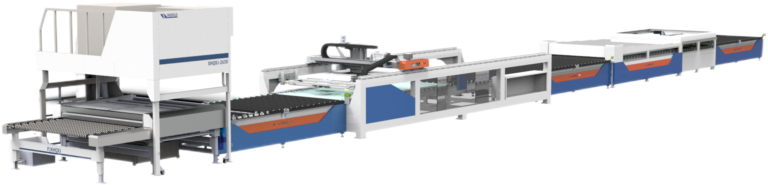

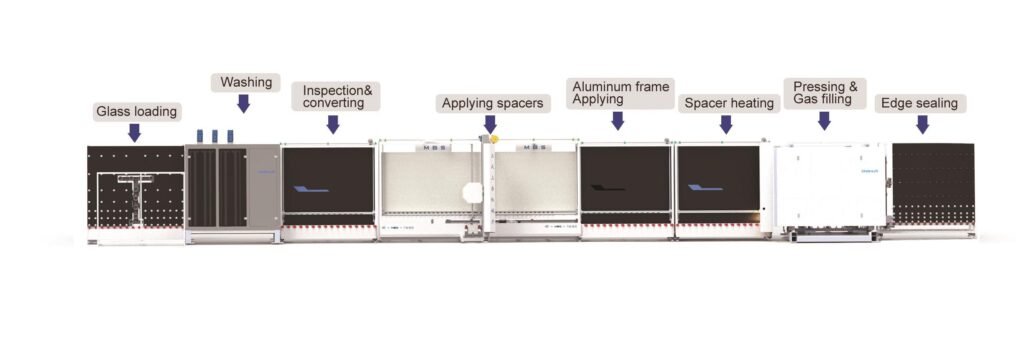

- Key Components of MBS VerticalIG Production Line:

- Washing Machines

- Spacer Application Systems: spacer type: flexible warm edge spacer

- Assembling system:

Intelligent heating system, heating the spacer independently

Press with on line gas filling

Coner Sealing Machine

- Optional Equipment:

Automatic glass loading and off-loading machine,

Sealing Robot

Edge deletion

- Choosing the Right Production Line for Your Business: You need to know the following specification

- Productivity Requirement:

- Customization Options Available

- Automation Level and functions you need

- Space and Layout Considerations:

- Energy Supply Requirement

- Why Choose MBS

- 15 years’ experience in developing and making IG production line

- After-Sales Support

Technical support, training, and spare parts 24/7 available

- Warranty and Service Agreements:

One-year warranties and ongoing maintenance.

- Spacer Applicator is easy to upgrade and link with other production line.

- Adapting to Market Trends:

Able to apply both aluminum bars and flexible warm edge spacers

Investing in the right insulating glass production line is a critical decision that can significantly impact your business’s efficiency, product quality, and profitability. By considering the factors outlined in this guide and contact us today for expert advice and the latest technology solutions tailored to your business!