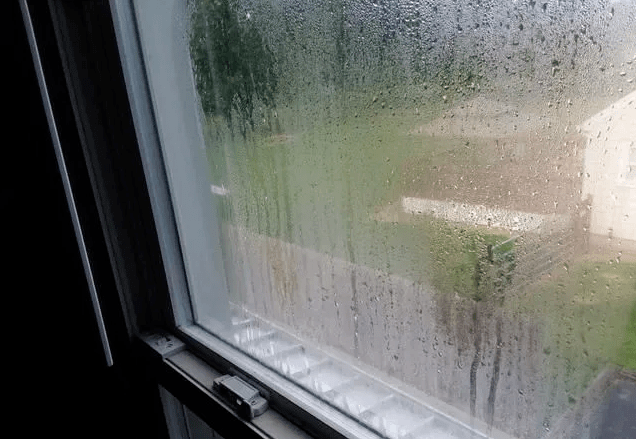

As global energy-efficiency standards continue to rise, the window and door industry is rapidly shifting toward high-performance insulating glass units (IGUs) and automated production. In this transition, Super Spacer warm-edge technology has become the preferred choice for an increasing number of manufacturers.

From thermal performance and long-term durability to manufacturing efficiency and cost control, Super Spacer is fundamentally transforming how high-performance IGUs are produced.

What Is Super Spacer?

Super Spacer is a fully non-metal, flexible warm-edge spacer made from a silicone-based, micro-porous, thermoset material. Its integrated structure combines:

• Desiccant

• Moisture vapor barrier

• Pressure-sensitive adhesive

• Butyl sealant

This highly integrated design eliminates metal thermal bridges and delivers superior durability compared with traditional aluminum or stainless-steel spacers. IGU fabricators with Super Spacer are commonly referred to as Super Warm Edge Insulating Glass Units.

Performance Advantages of Super Spacer

1. Ultra-Low Thermal Conductivity

As a 100% non-metal spacer, Super Spacer significantly reduces edge-of-glass heat transfer, improving the overall U-value of the window system and helping manufacturers meet stringent energy codes.

2. Outstanding Durability and UV Resistance

The thermoset material offers excellent resistance to UV exposure and aging, with a wide operating temperature range from –40°C to +121°C, ensuring long-term sealing performance in extreme climates.

3. 100% Elastic Recovery for Long IGU Lifespan

The flexible structure maintains constant sealing pressure during glass expansion and contraction, reducing seal failure and extending IGU service life.

4. Proven Across Multiple Applications

Beyond windows and curtain walls, Super Spacer is widely used in refrigeration, automotive, high-speed rail, and aerospace applications, demonstrating its reliability in demanding environments.

Why more and more fabricators choosing super spacer?

How to balancing time, quality, and cost is the key to produce high-performance insulating glass economically. Traditional IGU manufacturing relies heavily on complex manual operations. Extensive human involvement—particularly manual spacer framing—often results in inconsistent product quality while consuming significant production time and labor costs.

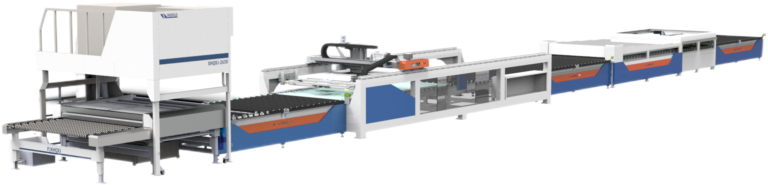

The continuous upgrading of automated equipment has dramatically improved the efficiency of producing insulating glass with Super Spacer technology. Automation effectively addresses the challenges IGU manufacturers face today, including labor shortages and growing demand for high-performance insulating glass. Fully automated IGU production lines significantly enhance both productivity and precision, especially for extra-large insulating glass units. Production efficiency can be increased by more than 50%, while easily accommodating IGU sizes up to 2.5 × 3.6 meters.

Today, Industry 4.0 automation has become a clear development trend. In addition to its ultra-low thermal conductivity, the advantages of flexible spacers (Super Spacer) are becoming increasingly evident. For example:

First, Super Spacer is supplied in continuous reels, free from the length limitations of traditional rigid spacers. It can be applied continuously from the spool, eliminating multiple joints and significantly improving both efficiency and accuracy in the production of large-format insulating glass.

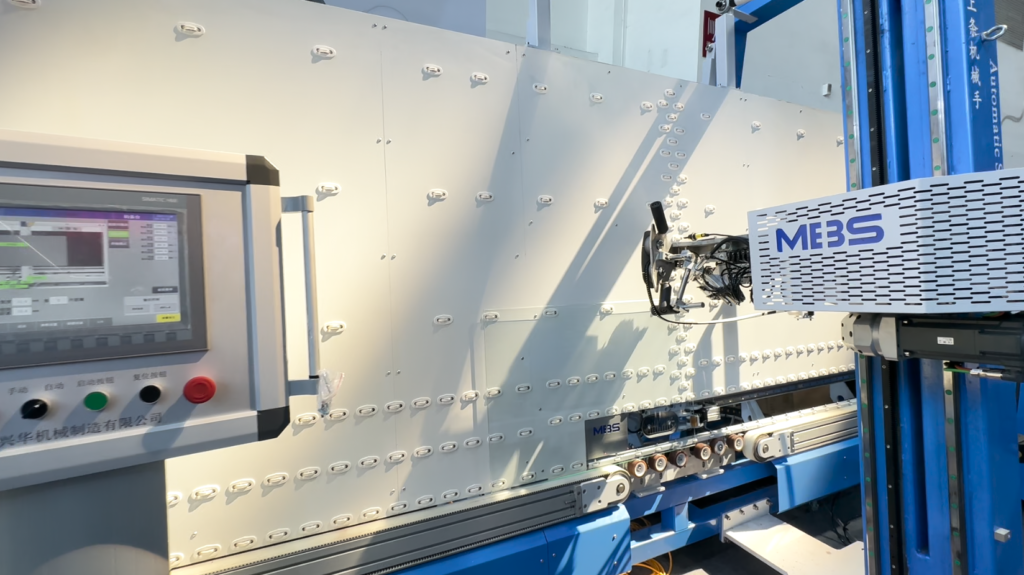

Second, as a fully non-metal material, Super Spacer is ideally suited for automated production. It eliminates many traditional IGU manufacturing steps, including spacer cutting, bending and corner assembly, joint insertion, desiccant filling, butyl application, and manual frame placement. These complex processes are replaced by robotic systems operating with high precision and consistency.

Super Spacer is applied smoothly by robotic arms down to the final millimeter, ensuring a perfect and long-lasting edge seal. From an aesthetic perspective, it delivers excellent straightness, precise 90-degree corners, eliminates glass panes misalignment in multi-cavity IGUs, and completely prevents butyl sealant squeeze-out.

Driving the Future of High-Performance IGU Manufacturing with MBS

As energy-efficiency regulations tighten and labor shortages continue to challenge manufacturers worldwide, the insulating glass industry is entering a new phase of transformation. Super Spacer warm-edge technology combined with advanced automation offers a proven solution to balance production speed, product quality, and manufacturing cost—the core priorities of modern IGU fabrication.

With its fully non-metal, flexible design, Super Spacer enables seamless integration into fully automated insulating glass production lines, delivering superior thermal performance, long-term durability, and flawless edge-seal aesthetics—even for extra-large IGUs up to 2.5 × 3.6 meters. What was once considered a premium option is rapidly becoming the standard for high-performance insulating glass.

At MBS, we specialize in automated Super Spacer applicator systems and insulating glass production lines designed to help IGU manufacturers achieve higher efficiency, consistent quality, and scalable production. Our solutions support Industry 4.0 manufacturing concepts, reduce labor dependency, and enable customers to produce next-generation warm-edge IGUs with confidence.

Ready to Upgrade Your IGU Production?

If you are looking to:

• Improve IGU thermal performance and edge-seal reliability

• Increase productivity by over 50% with automated Super Spacer application

• Produce large-format insulating glass with higher precision

• Reduce labor costs and process complexity

MBS is your trusted partner in automated insulating glass manufacturing.

Contact MBS today to learn more about our Super Spacer applicators, automated IGU lines, and turnkey solutions, and take the next step toward high-performance, future-ready insulating glass production.