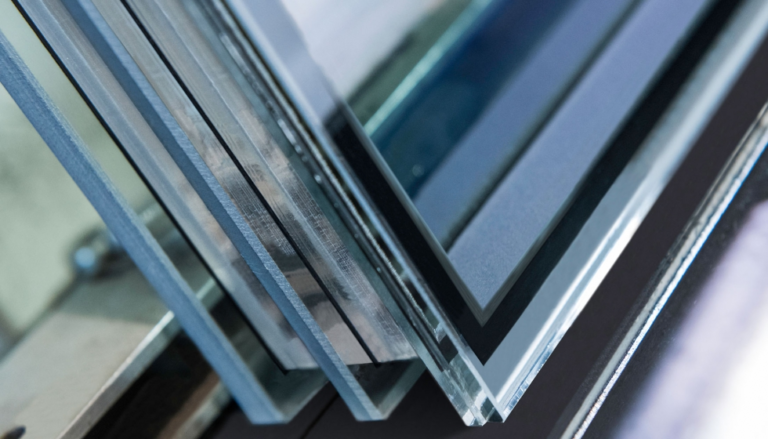

In recent times, due to various market forces, the demand for energy efficiency windows has been steadily increasing. It is now more important than ever to prioritize energy efficiency in window design.

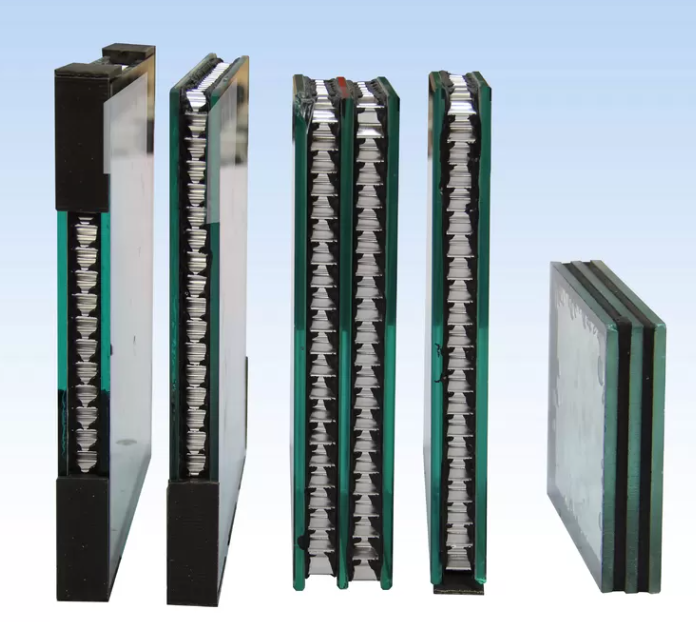

In the year of 1997, Truseal Company (now is operating by Quanex) has come up with a multi-layer IGU sealing solution now named Duraseal and Duralite. These product offers an option considering factors such as cost, manufacturing capabilities, thermal performance, and energy efficiency.

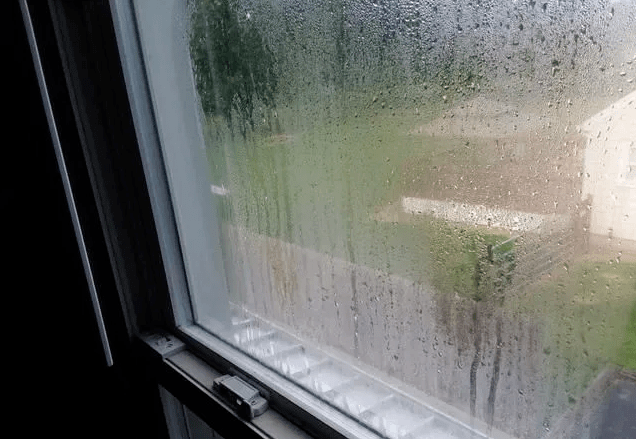

The advantages of the multi-layer spacer are truly remarkable. It not only boasts a smooth surface appearance but also provides superior argon gas retention and improved condensation resistance among other benefits.

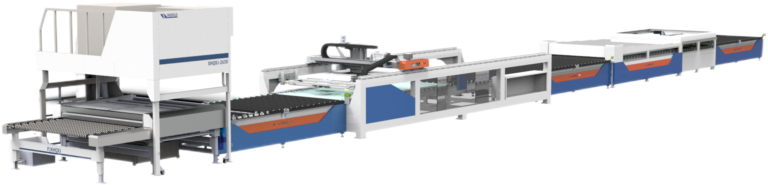

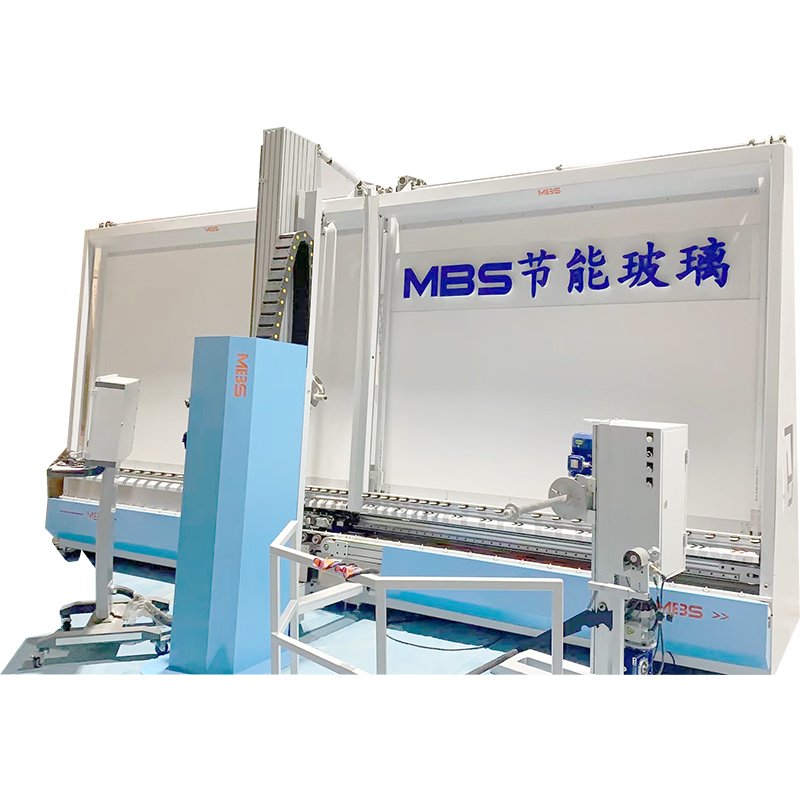

However, during the IGU production, the spacer applying part is the most important and skilled part. The manual application of the spacer often leads to inconsistent quality and low efficiency. To address this issue, Xinghua Machinery has developed an MBS spacer applicator for automatic apply the warm edge spacer.

This automated machine ensures precise and efficient spacer application and assembly. The spacer applied by this MBS spacer applicator is straight at the edge with perfectly angled corners.

The working speed is also impressive, it can apply the spacer (for 1m x 1m glass) in just 30 seconds. We also offer a whole production line with our vertical glass washing machine and press to form a whole IGU production line. This fully automatic double glazing glass production line requires only 2 operators, significantly reducing labor costs.

We are dedicated to promoting energy-efficient insulating glass within the window and door industry. MBS machines help our customer to do the work easily for high quality finished products. If you would like to know more about this solution or have any queries, please do not hesitate to reach out to us. We look forward to assisting you in incorporating our machines into your manufacturing processes. contact us