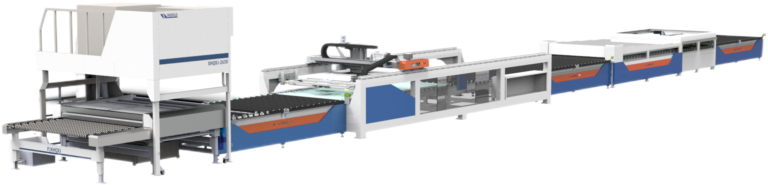

The demand for double glazed units with Georgian bars continues to rise as homeowners seek to combine traditional window aesthetics with modern energy efficiency. While manufacturing these units manually can be time-consuming and labor-intensive, MBS IG production lines are transforming how these intricate window systems are produced. Here’s how MBS IG production lines are revolutionizing the process, making it faster, more efficient, and cost-effective.

What MBS IG Production Lines Do?

MBS IG production lines are cutting-edge manufacturing systems designed to automate the production of insulated glass units (IGUs). These production lines incorporate advanced technologies to streamline every step of the IGU manufacturing.

Based on customer requirement MBS designed an automatic production line for double glazed units with georgian bars productions. This IG line automatic apply the flexible warm-edge spacer, which are essential for maximizing the energy efficiency of double glazed units.

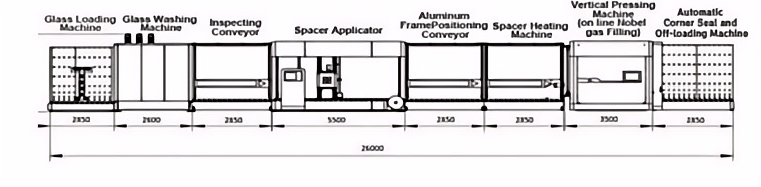

How the MBS Production line works?

- The system will check the washing machine status before glass panes entering the washing machine via the conveyor, if the washer machine has unfinished job the conveyor will stop and resume transporting after the job was done, alarm warning when input Low-E glass surface is reversed.

- The glass pane enters the washing machine, passes through all the soft bristles (3 pairs) and then goes to the air-drying section.

- Cleaned glass pane is accelerated and transmitted to the automatic measurement station for automatic measurement of glass size.

- When the spacer applicator is free, the glass pane will transmit to the spacer application. The first glass pane of the IGU is directly passed through, and the second glass pane of the IGU will automatically be applied the spacer.

- Before the glass pane transmitted to the press and gas filling machine via the second conveyor, the system will check the status of the press and schedule the entering time. a n

- (No gas filling mode) When the first glass pane of the IGU arrives to the press and gas filling machine, the machine lifts the glass pane up and the vacuum suction cup moves towards to grab the first glass pane and moves back to the rear panel of the machine to wait for the second glass pane. The second glass pane with spacers is lifted up after arrives to the press and gas filling machine. The front panel will move towards to the rear panel to press the two glass panes together.

- (Gas Filling mode) After both glass panes enter the press and gas filling machine. The bottom inflation head protrudes and the outlet gate closed before pressing. The adjustable barriers drive to the appropriate position to filling noble gas according to the IG size. Pressing to assembling the glass panes together after the gas filling completed.

- After assembling, the IGU is transported to the output conveyor, ready for the next process.

For Vinyl window manufacturers, this production line make it easier to meet growing market demands while delivering stable and high-quality products. If you’re looking to take your IGU production to the next level, MBS IG production lines are the solution you’ve been waiting for.