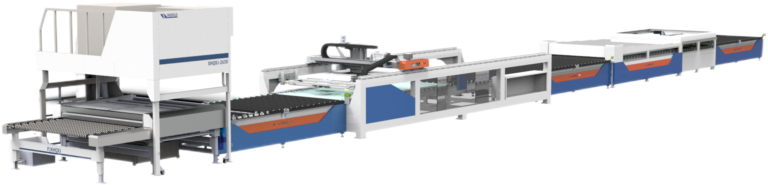

Selecting the right double glazing production line is crucial for any manufacturer in the glass and window industry. Whether you’re producing insulated glass units (IGUs) for residential or commercial applications, choosing between horizontal and vertical production lines can significantly impact your efficiency, quality, and overall production costs. In this article, we’ll explore the key factors to consider when deciding between horizontal and vertical double-glazing lines to help you make an informed decision.

Understanding Horizontal and Vertical Double Glazing Production Lines

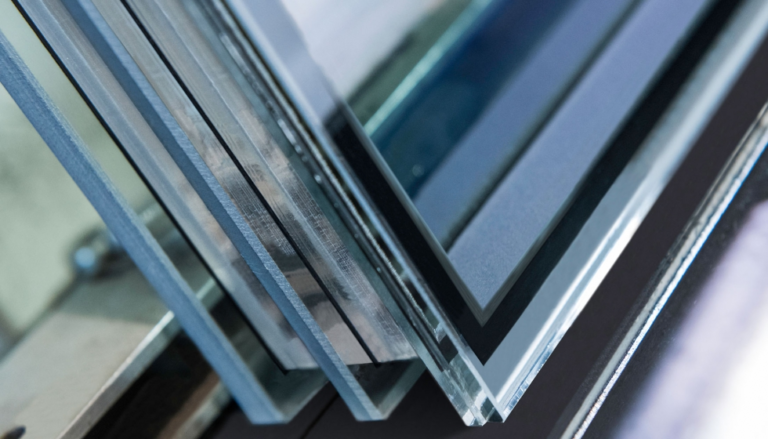

Before diving into the comparison, it’s essential to understand the basic differences between horizontal and vertical double glazing production lines.

Horizontal IG production lines: In this configuration, glass panes are processed while lying flat. The glass moves horizontally through the various stages of production, including cutting, washing, spacer application, gas filling, and sealing.

Vertical IG production lines: Glass panes are processed while standing vertically. The glass moves through the different stages of production while upright, which can lead to space-saving and more efficient handling in some manufacturing environments.

Factors to Consider When Choosing a Double Glazing Production Line

- Spacer Availability

One of the most significant factors in choosing between horizontal and vertical production lines is the available floor space in your facility.

Horizontal line typically requires more floor space since the glass moves along the production line while lying flat.

Vertical line is more space-efficient as the glass is processed in an upright position, which can allow for a more compact footprint in smaller production areas.

If your production space is limited, a vertical double glazing line may be the better choice for maximizing your facility’s efficiency.

- Type of Glass and Product Specifications

The type of glass and the specific products you manufacture play a crucial role in determining which production line is most suitable.

Horizontal lines are often preferred for processing thick, or heavy glass panels, such as architectural glass or fireproof glass. These lines provide greater stability during production, reducing the risk of glass breakage.

Vertical lines are typically ideal for standard-sized IGUs, thinner glass, or products that require faster cycle times. These lines can handle high-volume production with precision and consistency.

If your production focuses on thick glass, a horizontal line may offer better stability, while standard or high-volume IGU production may benefit from a vertical setup.

- Production Volume and Speed

Your expected production volume and the speed of your operation are also critical factors to consider.

Vertical lines often offer faster cycle times due to their more compact and automated processes, making them an ideal choice for high-volume manufacturers.

Horizontal lines, while slightly slower, are often capable of handling larger or more complex products with a higher degree of customization.

If speed is your priority, a vertical production line may provide the efficiency you need for high-output operations, while horizontal lines can be more suitable for customized or specialized products.

- Automation and Labor Costs

The level of automation in your production line can have a significant impact on labor costs and production efficiency.

Horizontal lines tend to have more manual elements, which can lead to higher labor costs but may offer more flexibility for custom or non-standard glass products.

Vertical lines are more automated, which can reduce labor costs and minimize errors, leading to more consistent quality and faster production.

For manufacturers looking to automate their processes and reduce labor costs, a vertical production line with advanced automation features may be the best choice.

- Cost and Investment

The cost of acquiring and installing a double glazing production line can vary based on the configuration and level of automation.

Horizontal lines are generally more affordable upfront, but the ongoing operational costs, including labor, may be higher.

Vertical lines tend to have a higher initial investment, but the potential savings in space, labor, and operational efficiency can make them a more cost-effective solution in the long run.

Budget considerations are important, but it’s also essential to think about the long-term return on investment (ROI) when choosing between horizontal and vertical lines.

Choosing between a horizontal and vertical double glazing production line depends on several key factors, including your facility’s space, the type of products you manufacture, production volume, and budget.

– If you’re focused on producing large, heavy, or custom glass products, a horizontal insulating glass production line might be the best fit for your needs.

– For manufacturers looking to maximize efficiency, space, and reduce labor costs a vertical IG production line with advanced automation could offer the best solution.

Ultimately, the decision should be based on your specific production requirements, with careful consideration of both short-term and long-term business goals. Consulting with experienced suppliers and understanding the capabilities of each type of production line will ensure that you make the right investment for your double glazing business.

For more information or to explore our range of double glazing production lines, contact us today to find the perfect solution for your manufacturing needs.