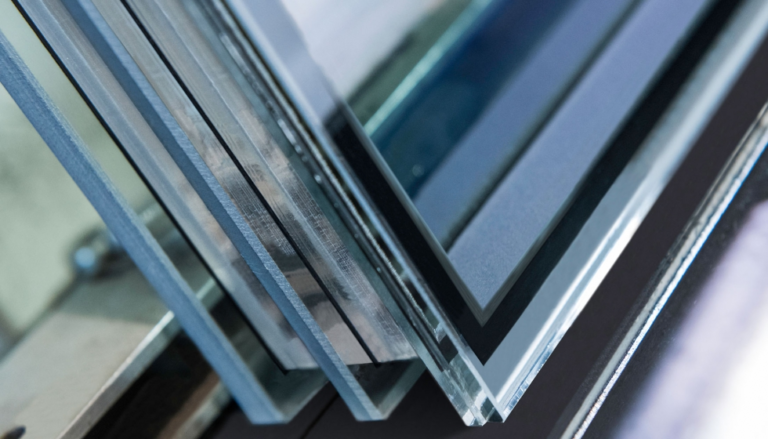

Are you striving to enhance the market competitiveness of your insulated glass units (IGUs)? Transitioning from traditional rigid spacer applications to innovative flexible warm-edge solutions could be the strategic move your business needs. This blog explores how flexible warm-edge spacers not only improve thermal efficiency but also offer a range of other benefits, from durability to reduced labor costs, particularly when integrated with MBS IG production lines.

- The Advantages of Flexible Warm-Edge Spacers

- Improved Thermal Performance: Flexible warm-edge spacers reduce heat transfer at the glass edge, leading to better energy efficiency.

- Enhanced Durability: These spacers are designed to withstand temperature fluctuations, ensuring a longer lifespan for your IGUs.

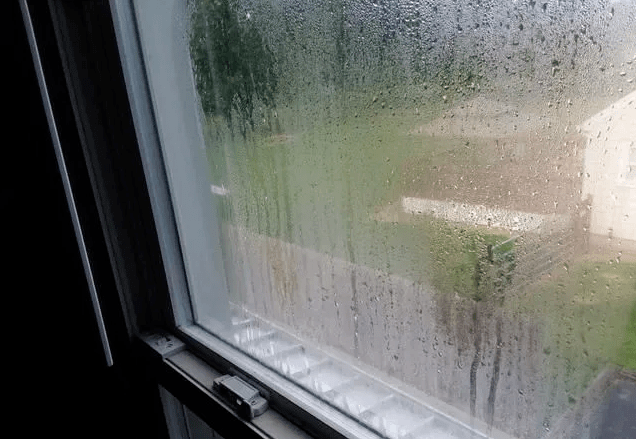

- Condensation Resistance: By minimizing thermal bridging, flexible warm-edge spacers help in reducing condensation, thus maintaining clarity and cleanliness.

- Aesthetic Appeal and Acoustics: The sleek design of flexible warm-edge spacers not only looks better but also contributes to better sound insulation.

- Cost-Effectiveness Despite Higher Material Costs

With rigid spacer bar, the fabricator must assemble many components offline into a spacer bar frame (spacer bar, joiner keys, primary sealant, desiccant, etc.) Flexible Warm-Edge spacers assemble by automation streamlines that process, reducing up to 60% in labor.

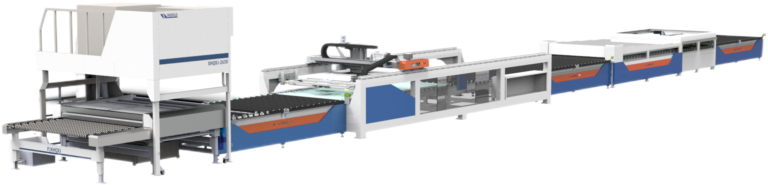

- MBS Fully automatic IG Production Lines

- Reduced Human Touchpoints: Implementing MBS IG production lines can minimize human errors, ensuring consistent quality across all units.

- Fewer Personnel Needed: The automated nature of MBS IG lines means fewer workers are needed, reducing labor costs and increasing production efficiency.

- Upgrade Your Production Line for Market Competitiveness

- Dual-Use Capabilities: MBS solutions offer the flexibility to upgrade existing IG lines, meeting current market demands and maximizing ROI.

- Long-Term Benefits: Investing in flexible warm-edge spacers and MBS production lines now can position your business ahead of the competition.

Conclusion:

The transition to flexible warm-edge spacers, complemented by the advanced capabilities of MBS IG production lines, offers a holistic approach to improving IGU production. Not only do you enhance the thermal performance and overall quality of your products, but you also achieve significant cost savings. Ready to upgrade your production line? Contact us today to explore how we can help you stay ahead in the market.

Call to Action:

“Get in touch with us to learn more about flexible warm-edge spacers and how MBS IG production lines can revolutionize your IGU manufacturing process.”