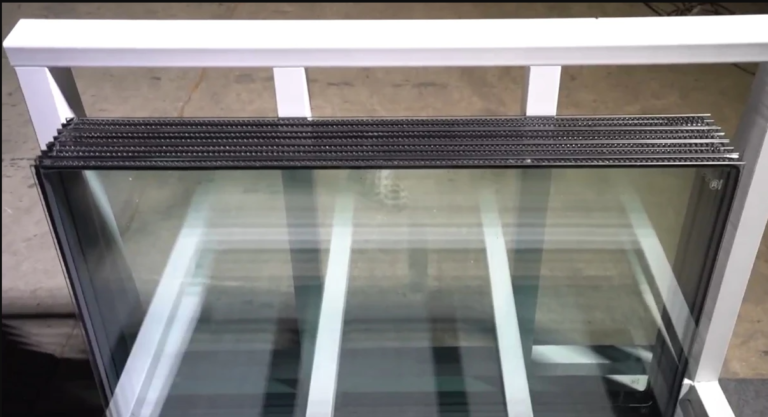

In the competitive market of glass refrigerator doors, quality and energy efficiency are crucial. These doors need to provide clear visibility, effective insulation, and energy savings. As a leading insulating glass line manufacturer, we are proud to support our customer, Hangzhou Huafa Industrial Co., Ltd. in achieving exceptional results by implementing our MBS warm edge spacer technology. With our MBS insulating glass production line, Hangzhou Huafa has improved production efficiency, reduced costs, and boosted product quality.

Why Quality Glass Refrigerator Doors Matter

Glass refrigerator doors are essential in refrigeration systems, influencing both the appearance and the performance of the units. For manufacturers like Hangzhou Huafa, producing high-quality glass doors that meet rigorous thermal, aesthetic, and durability standards is vital. A high-quality refrigerator glass door ensures:

Enhanced Thermal Efficiency: Keeps cold air contained and reduces energy consumption.

Condensation Control: Prevents fogging for a clear view of the contents.

Cost Efficiency: Reduces the need for frequent maintenance and extends product life.

Aesthetic Appeal: Enhances visual presentation, which is crucial for commercial displays.

MBS Warm Edge Spacer Technology: Key to High-Performance Insulated Glass

MBS warm edge spacers are a top choice for manufacturing high-performance insulated glass refrigerator doors. When paired with our MBS insulating glass line, this technology provides several significant benefits:

- Optimized for Cold Temperatures

MBS warm edge spacers are engineered to perform well in low-temperature settings, making them ideal for glass doors in commercial refrigeration applications.

- High Efficiency with Single-Seal Design

Unlike traditional spacers, MBS warm edge spacers do not require a secondary sealing process. This single-seal design not only improves production efficiency but also reduces material and production costs.

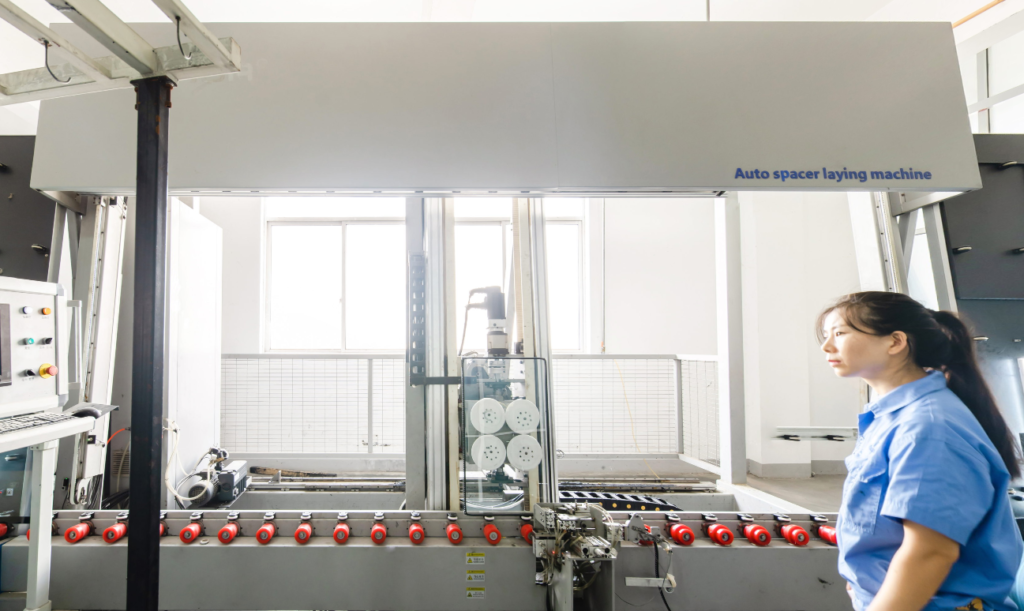

- Labor Cost Savings with the MBS Insulating Glass Production Line

By utilizing our advanced MBS insulating glass production line, manufacturers like Hangzhou Huafa benefit from reduced labor costs. The streamlined process minimizes manual work, increasing both efficiency and quality control.

How Our Insulating Glass Production Line Supports Hangzhou Huafa’s Success

Established in 1994, Hangzhou Huafa has grown to become a leading supplier of high-quality glass doors for refrigeration, serving both domestic and international markets. With our MBS insulating glass line, Hangzhou Huafa has been able to achieve efficient, cost-effective production while maintaining top standards in quality. By using MBS warm edge spacer technology, they have further optimized their production process, offering energy-efficient, durable, and aesthetically pleasing glass doors to their clients around the globe.

The Best Solution for Refrigerator Glass Doors

For glass refrigerator door manufacturers who prioritize quality, efficiency, and cost savings, the combination of MBS warm edge spacer technology and our insulating glass production line offers the ideal solution. This technology provides manufacturers with a high-quality product that meets market demands for energy efficiency, condensation resistance, and premium appearance.

What Our Clients Say