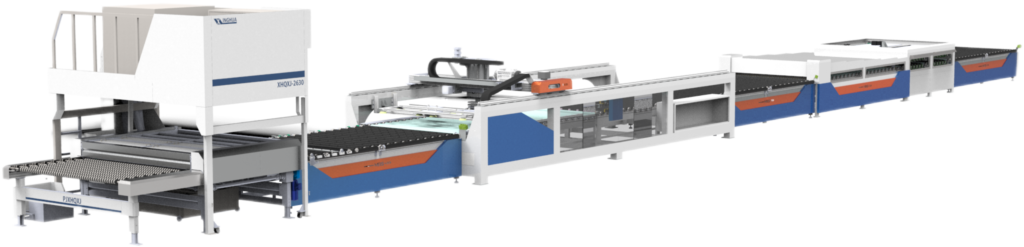

When it comes to fire-rated glass production, precision, efficiency, and sealing quality are non-negotiable. That’s why leading manufacturers are turning to MBS’s fireproof glass production line, which is equipped with a patented horizontal glass rotating spacer applicator system—an innovative technology that sets a new benchmark for performance in fireproof glass manufacturing.

Patented Horizontal Glass Rotating Spacer Applicator

At the heart of MBS’s high-performance fireproof glass line is its patented horizontal glass rotating spacer applicator method. This advanced system, developed in-house by MBS Glass Machinery, offers unmatched advantages in sealing fire-resistant glass with both speed and accuracy. Here’s what makes it superior:

1. Short Tape Supply Channel

The unique design of the applicator minimizes the tape supply channel, making it compatible with a wide range of fireproof tapes from 3mm to 20mm. This not only expands your tape selection but also supports the use of larger, more robust sealing materials—ideal for high-performance applications.

2. Simple and Heated Tape Change System

MBS’s tape changing mechanism is designed for maximum operator convenience. The material box is heatable, making it easier to maintain optimal tape flexibility during application. With minimal steps needed for replacement, production downtime is significantly reduced.

3. Real-Time Tape Monitoring During Application

The applicator provides an open visual access point to monitor tape conditions during operation. This allows operators to identify damage or inconsistencies immediately, improving quality control and reducing the risk of sealing failures.

4. No Need for Separate Laminating Equipment

With MBS’s integrated design, tape application and laminating happen simultaneously—eliminating the need for a separate laminating unit. This not only saves space but also simplifies the production line and lowers equipment costs.

5. Faster Film Feeding and Discharging – No Waiting Time

Thanks to the efficient applicator layout, there is no need to pre-store laminated films. The glass feeding and discharging rhythm is accelerated, boosting throughput and improving cycle time without compromising sealing precision.

6. Mobile Edge Heating for Even Tape Activation

Before rolling, MBS uses a mobile edge heating method, ensuring the tape is evenly heated along the entire edge. This process improves adhesive activation and bonding strength, which is critical for fire-rated glass performance.

7. Progressive 14-Pair Roller Pressing System

The MBS hot press features a 14-pair progressive roller design that presses the tape smoothly and consistently. This method avoids sudden pressure spikes and ensures uniform sealing thickness—essential for durability and thermal resistance.

8. Accurate Glass Pressing for Consistent Layer Thickness

Precision in multi-layered fireproof glass is vital. The MBS line guarantees tight tolerance in pressing dimensions, resulting in minimal error between cavity layers. This leads to improved insulation performance and fire resistance stability.

MBS Is the Preferred Choice for High-Performance Fireproof Glass Lines

With its patented technology, modular design, and cutting-edge sealing process, the MBS fireproof glass production line is engineered for manufacturers who demand the highest standards. From faster production cycles to superior sealing quality, MBS delivers a reliable solution that ensures every glass panel meets strict fire safety and structural performance requirements.

If you’re looking to upgrade your fireproof glass production capabilities, MBS offers the proven technology and technical support to keep your operations ahead of the curve.

Contact MBS Glass Machinery today to learn more about our fire-rated glass production solutions or request a demo.